Starting or establishing a business, in itself, is already a risk; you never know when you can get the investment you’ve put to it; you never know what the outcome will be – and most importantly, you wouldn’t be able to figure out how you can manage your business wisely and appropriately for you to arrive at the results you want. In our time now, a lot of business and company owners are lucky because of the fact that there are tons of different methodologies out there that can help and assist them with the requirements they have – one of which is Lean Six Sigma.

What is Lean Six Sigma?

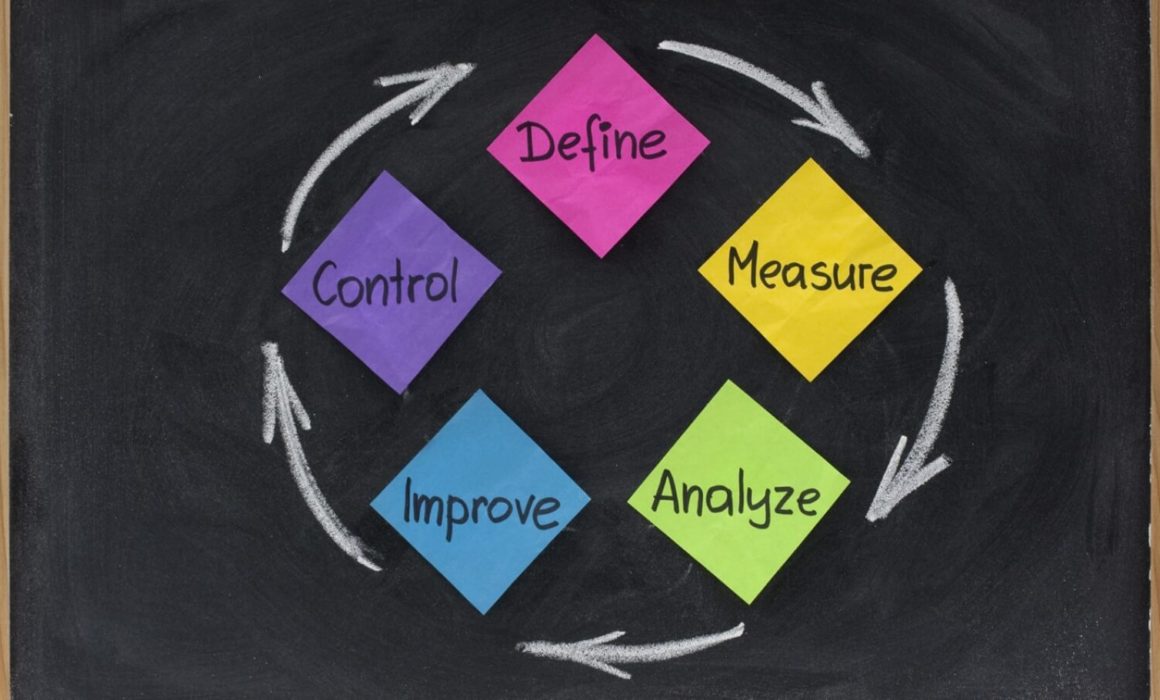

Lean Six Sigma is a problem-solving methodology that relies on data, statistics, and company or business history to arrive at a resolution that would yield the best and the most accurate results. It’s proven and tested by millions of companies from all around the globe including your favorites such as Starbucks, Coca-Cola, 3M, Toyota, and many more.

When it comes to the Return on Investment (ROI), you can use some of the tools and the techniques used in Lean Six Sigma for you to arrive at the most feasible time of the ROI that you’ve been wanting to get. However, if you’re not that adept in the industry, you can call us here at Maximum Potential for a consultation. Our company has been looked at and regarded by many people as the go-to company for all of their needs when it comes to Lean Six Sigma.

As a matter of fact, we’re known as the company that innovated in inculcating Lean Six Sigma into the curriculum of High School Students.

What’s an ROI Consultant?

As concrete as what it is, an ROI or a Return of Investment Consultant is a Consultant that can give advice to a business on when they can get or receive the investment back that they’ve spent with their company. At Maximum Potential, we have the best Consultants in all platforms, from Lean Six Sigma Consultants, ROI Consultants, even coaches, and instructors – we’re you’re all-in-one place!

Other than being the full-service, complete-package Lean Six Sigma Consulting and Training Company we are, many businesses also see the relevance and the importance of the ROI Consulting Services we offer.

Maximum Potential’s ROI Consulting

By following and living by the Lean Six Sigma Practices that we teach and preach, we are able to provide our clients with projections, predictions, as well as guides on how they can get the ROI they look to have. Through the careful and delicate studying and observation, we do here at Maximum Potential, we are adept and skilled in helping our clients dissect whatever’s happening with their business. And in our experience, we never leveled with the expectations of our clients and customers – we were always at the top; always going above and beyond what they expect from us and our bundle of services.

Delivering Finest Services

Being the best company and training institution in the Lean Six Sigma industry, it is very well expected of us to provide a whole wide range of successful and effective services to our clients. Although most clients expect premium service from us and they get it, a lot of them don’t expect that we perform and we complete other services and types of consultancy too.

With Maximum Potential, you can literally receive the highest quality and highest caliber of services you need. The expertise and the overall adeptness we have in the industry is superb – and we’re more than just what you think of us. It doesn’t matter what business industry you’re in, so long as you need help with your business – whether you want our assistance in terms of improving and developing business processes, or if you are looking for a more serious type of financial concern, you can always count on us and our team of professionals and consultants.

Why Choose Us?

There are many other Lean Six Sigma Consulting and Training Companies out there in the market, why should you spend time communicating and interacting with us? How are we different than the rest?

Herewith us at Maximum Potential, we offer a whole wide range of services and features to our clients. From the Lean Six Sigma Training and Certification we offer, to the in-depth ROI Consulting Services that you’ve been looking for, we got it all for you. Through the comprehensive and complete array of services we offer, you will never feel the need to look for a different company ever again. You can call us or you can contact us through email and we will be ready to answer all of your questions and queries.

Work with the best and bring your company’s fullest potential to life. Spend the minimum amount while you get the best value for your money!