Being one of the most sought after and the most wanted business development and improvement processes, we all know that the main goals of Lean Six Sigma are to:

- Reduce or totally eradicate waste and problems

- Improve and develop business processes

- Maximize the efforts and the skills that your professionals have

- And many more

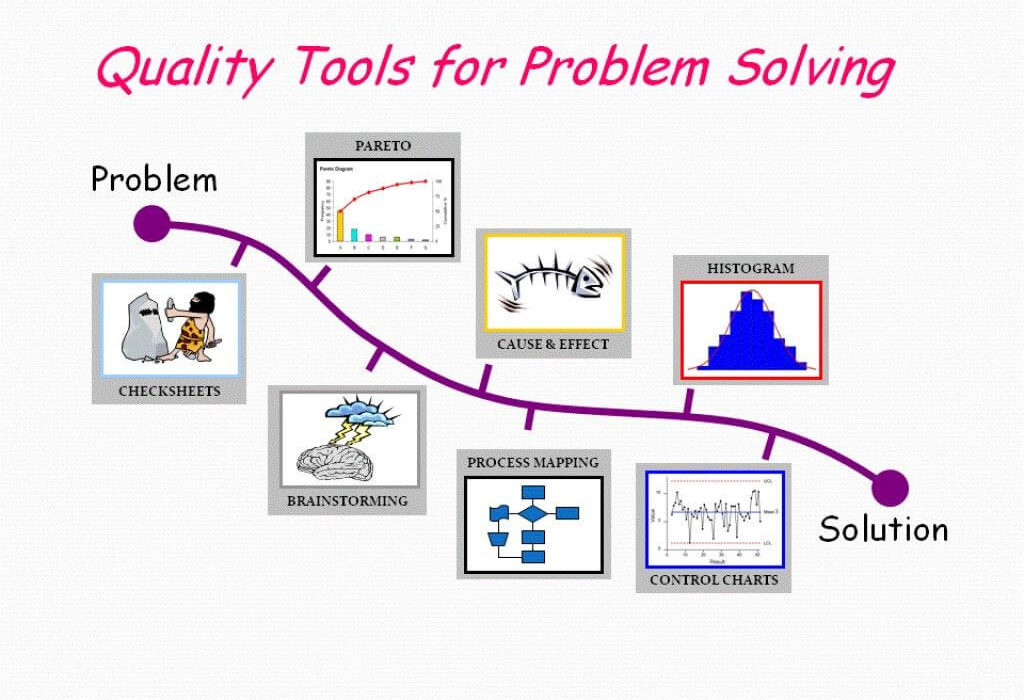

Those are only the most common reasons why Lean Six Sigma is taken up — and it’s for the betterment and the efficiency of business processes. There are tons of different tools and resources used in the Lean Six Sigma Improvement Process and among the most used and the favorite is the Fishbone Tool. We here at Maximum Potential are excited to share with you and Describe Lean Six Sigma Fishbone Tool so you’ll be aware of it.

What is the Fishbone Tool?

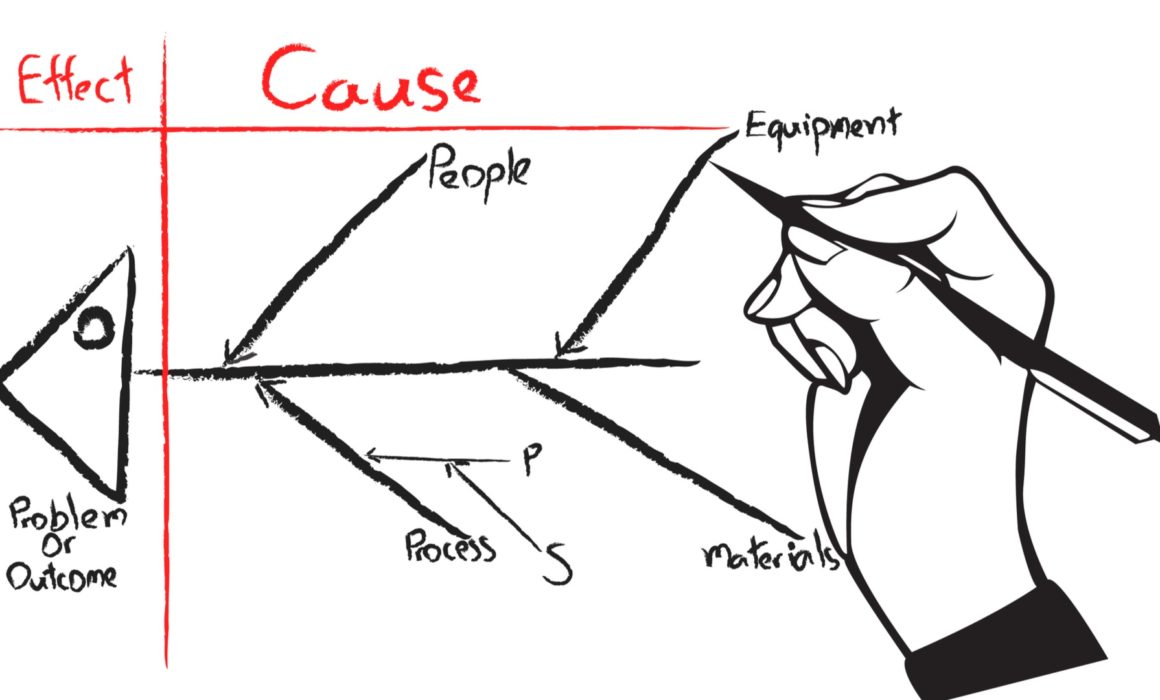

Also known as the Fishbone Diagram, it’s one of the tools and resources used in Root Cause Analysis (RCA) or the process that pinpoints the base or the foundation of a certain problem. There are a lot more — many just prefer using it especially in problems that have a lot of different possible causes and problems that have simultaneous cases. The Lean Six Sigma Fishbone Tool is as literal as its name — it’s a diagram that takes the shape of a fishbone and it’s used to determine problems that can detail a cause of a certain problem, as well as the effect that it has — and it’s used for a specific hurdle that can be yielded by multiple causes and effects. It’s also known as the Ishikawa Diagram and is used for the “cause-and-effect.”

How We Describe the Lean Six Sigma Fishbone Tool

Describing the Lean Six Sigma Fishbone Tool is not as difficult as you think, as a matter of fact, it’s simple and we highly recommend it to everyone when detailing out and listing out problems.

Process Identification – 1st Step

The process is simple, we here at Maximum Potential teach it to all our students and learners in the easiest ways we can — we can teach and educate you as if you’re 5! The first step is to identify the process you’re looking to improve.

You can look at any process or business procedure you perform in your company that you want to improve or develop.

Categories – 2nd Step

Once you find the problem out, the next step is to identify the main categories of a certain process. If you work in the manufacturing section, the categories could be People, Machinery, Methods and Processes, Materials and/or Suppliers, Working Conditions, and so on.

Cause Identification – 3rd Step

The last but definitely not the last step is to detail and provide the causes that you see based on your company or your business’s performance. Each category should have one cause and under it, detail it to the lowest and the least problem possible.

Going back to the same manufacturing example, under the “People” category, it could be because they’re not trained, they work slow, they start late; under the “Machinery” category, the causes could be improper maintenance of the machines, old machines; under “Processes,” incorrect procedures, inefficient processes — you get the point.

When you finish the diagram, the next thing to do is to analyze it with your consultant (internal or external) to see if what you arrived at is accurate and precise. You can change and revise causes and categories as needed but the point of the Lean Six Sigma Fishbone Tool is for you to be able to visualize the cause-and-effect that you have within your business processes.

Importance of the Fishbone Diagram

The main importance and benefit of the Fishbone Diagram compared to other diagrams is the fact that it highlights each category with subtopics and subcategories below it. Unlike regular diagrams and charts, you might find it harder or more difficult to translate and read data or information; but with the Fishbone Tool, you’ll see it clearly and you’ll be able to see the root cause of certain problems.

Maximum Potential is the expert in helping students, companies, and businesses in creating these types of diagrams and resources that they can use for their perusal. As a company with over 150 years of experience, we’ve always been seen as the best and the most reliable company in the industry because of the material and the essence of what we teach our students and our learners.

In our experience, we never failed any of our clients in helping them reach what they wanted and what they essentially needed. Through the expertise and the overall skill of our consultants, coaches, and instructors, we’ve provided accurate resolutions and precise decisions that helped them in their journey.

If ever you find your business or your company under the same scenario, don’t hesitate to contact us here at Maximum Potential — the best Lean Six Sigma Training and Consulting company in the industry!